In the realm of advanced manufacturing, efficiency and precision are paramount. As industries strive for improved productivity while maintaining quality, 5-axis machining has emerged as a revolutionary solution. This cutting-edge technology not only enhances the capabilities of traditional machining but also significantly optimizes production processes. This article delves into how 5-axis machining transforms the manufacturing landscape by improving efficiency and accuracy.

Understanding 5-Axis Machining

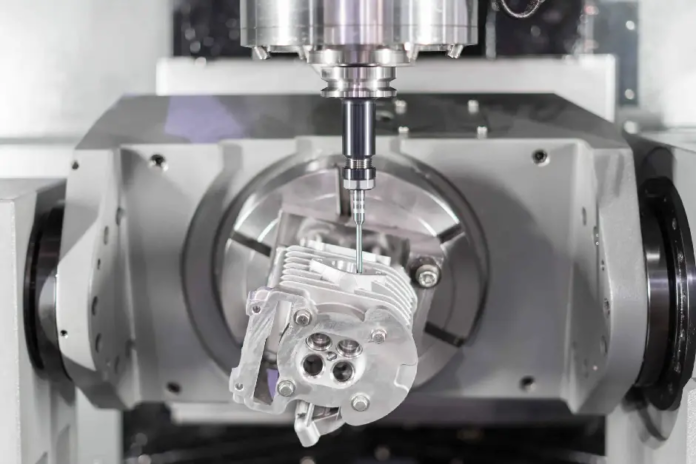

5-axis machining refers to a computer numerical control (CNC) process that allows simultaneous movement of a cutting tool along five different axes. Unlike traditional 3-axis machining, which restricts movement to the X, Y, and Z axes, 5-axis machining incorporates two additional rotational axes. This capability enables complex geometries to be machined in a single setup, thereby reducing the need for multiple setups and the risk of inaccuracies associated with repositioning.

The two additional axes allow the cutting tool to approach the workpiece from various angles, leading to intricate designs that would be challenging or impossible to achieve with conventional methods. This flexibility is crucial in industries that demand high precision, such as aerospace, automotive, and medical device manufacturing.

Enhancing Efficiency Through Reduced Setup Times

One of the most significant advantages of 5-Axis Machining is its ability to reduce setup times dramatically. Traditional machining often requires multiple setups to achieve the desired geometry, leading to increased production time and higher labor costs. With 5-axis machining, complex parts can be completed in a single setup, minimizing downtime and optimizing the workflow.

The efficiency gained from reduced setups is further enhanced by the automation capabilities of modern CNC machines. Advanced software can automate toolpath generation, ensuring optimal cutting strategies that maximize material removal rates while minimizing tool wear. This not only streamlines the machining process but also allows for consistent part quality, as variations between setups are eliminated.

Improving Accuracy and Precision

In manufacturing, precision is critical. The slightest deviation can lead to costly rework or scrap, negatively impacting overall productivity. 5-axis machining enhances accuracy by allowing the cutting tool to maintain a constant distance from the workpiece, regardless of the machining angle. This capability significantly reduces the risk of errors associated with tool deflection and vibration, ensuring that parts are produced to the exact specifications.

Moreover, the ability to machine complex geometries in a single setup minimizes the cumulative error that can occur with multiple setups. This is particularly beneficial for industries such as aerospace, where components must meet stringent tolerances to ensure safety and performance. By investing in 5-axis machining, manufacturers can achieve tighter tolerances and higher-quality finished products.

Expanding Design Possibilities

The flexibility of 5-axis machining opens up new possibilities for product design. Designers and engineers can explore complex geometries that were previously deemed impractical. This capability allows for innovative product designs that can enhance functionality, reduce weight, and improve overall performance.

For instance, in the aerospace industry, 5-axis machining can produce lightweight components with intricate internal features that optimize airflow and reduce drag. Similarly, in the medical field, custom implants and surgical instruments can be manufactured with precise fit and function, leading to improved patient outcomes.

Cost-Effectiveness Over Time

While the initial investment in 5-axis machining technology can be significant, the long-term benefits often outweigh the costs. The reduction in labor and setup times, coupled with improved accuracy, leads to increased throughput and lower operational costs. Furthermore, the ability to produce complex parts in a single setup can reduce material waste and decrease the need for secondary operations, further enhancing cost-effectiveness.

Many manufacturers find that the return on investment (ROI) for 5-axis machining becomes evident within a relatively short period. As production processes become more efficient and output increases, businesses can allocate resources more effectively and explore new markets or product lines.

Conclusion

5-axis machining represents a paradigm shift in the manufacturing landscape, revolutionizing production processes by enhancing efficiency and accuracy. With its ability to reduce setup times, improve precision, expand design possibilities, and provide long-term cost benefits, this advanced technology is becoming increasingly essential for manufacturers looking to remain competitive in a fast-paced industry.

As businesses continue to embrace automation and advanced manufacturing techniques, 5-axis machining stands out as a key driver of innovation, enabling companies to meet the ever-evolving demands of their markets. Investing in this technology not only improves production capabilities but also positions manufacturers for sustained success in the future.